For most process plants, it’s not possible for all automation system components to be installed in non-hazardous areas. As a result, some form of protection is required to prevent fires and explosions that could occur when a hazardous gas and energy source combine. Fortunately, there are standards and associated products that if properly designed, installed and maintained virtually eliminate the risk of an accidental explosion in hazardous areas.

Hazardous Area Automation

Our Engineers at Highscope will help in optimizing your automation in the hazardous location. Generally we help the customer to choose between one of the three main method of protections such as Energy Limiting, Containment or Segregation. We can offer solutions either using IEC zone classification system or the NEMA class and division system.

Some of our standard Hazardous area solutions are

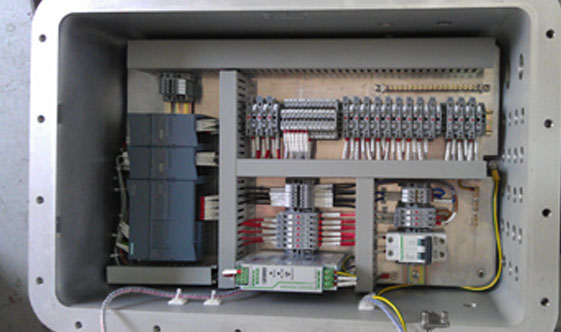

- Purge & pressurized PLC control panel

- Explosion proof PLC control panel

- Intrinsically safe PLC control panel

- SIL 1,2 & 3 based PLC control panel

- Fire and Gas system

- ESD (Emergency shutdown) system

- Asset management interface (HART) Panel

- Thin client HMI panel for Zone1 or 2

- Containerised operator control room

- Burner management system

- Flare control panel

- Relay panels (2 out of 3 voted)

- Custom build (SS316L) panel fabrication

The process package builders has to supply PLC based control system to the main contractor and also has to integrate it with clients existing DCS and asset management system. At Highscope we are able to customize the PLC control panel so that the conventional 4-20mA signal is used for Process control and instrument diagnostic information is connected to plant asset management system. Depending on the customer requirement we can also get our panel certified by third party to various international.

We offer solution to the following industries

- Fuel gas treatment / conditioning plant

- Produced water treatment

- Gas sweetening plant

- Induced Gas floation units

- Glycol dehydration unit

- Liquid fuel forwarding package

- Early production facility

- Central production facility

- Fuel farm storage system

- Sea water injection package on FPSO

- Sulphur Handling system

- Cement plants

We also offer containerised solution for your operator control room which will house your LV switchgear panels (MCC), PLC control panel, HVAC system, operator station, distribution boards (MDB,SMDB DB) fully wired, fitted and tested. We design this solution for harsh environment. We can also add generator control and synchronisation panel in the above solution so that client is able to operate with liquid fuel for power generation.