One of the most crucial decisions in the initial design phase of a process package or plant is the selection of the control system. First thing is to identify if there is any requirement for automating your process. If yes then the type of controls required to automate it. The challenges faced by today’s process industries have been multiplied by the volatile state of the global economy. In this type of environment the demands on the process control system are increased, going beyond simple regulatory functions. It becomes a tool to manage the plant, decrease energy consumption, reduce costs, cut emissions and provide quick and precise information from the field to support production and business decisions.

Process Automation

Highscope engineering can identify a control system not only based on your process but also based on the budget constraint that you have. Our advantage lies in the fact that since we are working with various automation manufacturer we are able to come up with very custmoised and apt solution for your process automation requirement.

Our ground breaking process control system design will stand up for top level efficiency in process control. Our design of control system will include the automation of all ancillary, upstream and downstream processes and will offer you a whole host of benefits. We offer solutions right from a small pumping stations right through to a large plant network.

Some of our standard process automation products are as follows

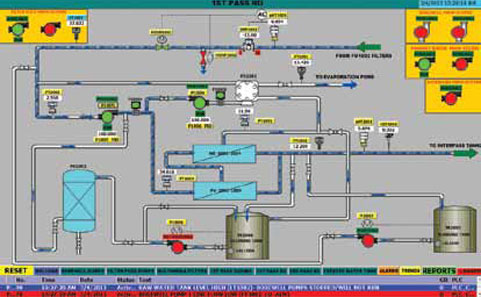

- PLC Control panel with HMI or Touch screen

- PLC Control panel with SCADA system

- Remote Terminal units (RTU) with display.

- Smart or programmable relay logic panel with display.

- Condition monitoring system (for your pumps).

- Alarm annunciator system.

- Relay Logic based control panels (Conventional type)

- Marshalling cabinets.

- Interposing relay panels.

- Chiller sequencing control panel.

We offer solutions to the following industries

- Reverse Osmosis plant

- Desalination plant

- Sewage treatment plant

- Industrial waste water treatment

- Inlet Head works for STP

- Automatic waste collection system

- Strom Water pumping station

- Irrigation Pumping station

- Water transmission pipeline monitoring

- Fruit & Vegetable cold storage panels

- HVAC System for complete plant

Since we deal with Pump Starters & VFD panels we can flawlessly interface our PLC system with existing or client’s LV switchgear and MCC panels. We train our PLC engineers in commissioning VFD’s and DOL starters. We also suggest / procure commissioning spares, operational spares or 5 years spares parts list based on the client requirement with all our control panels.